What is a Automatic Strapping Machine?

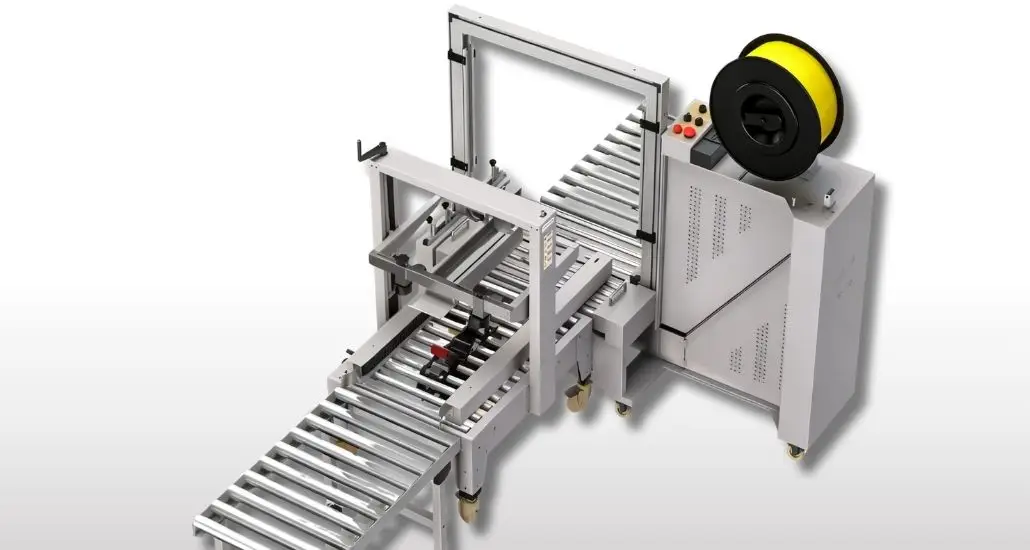

An Automatic strapping machine (also referred to as a banding machine or bundling machine) is an automated or semi-automated packaging system. It applies a strap—typically made from plastic, steel, or other durable materials—around a single product or a bundle of items.

After feeding the strap around the load, the machine tensions it to a specified force (to ensure a secure fit without damaging the goods) and seals the strap ends together. This creates a tight, stable unit that’s protected during shipping, handling, or storage.

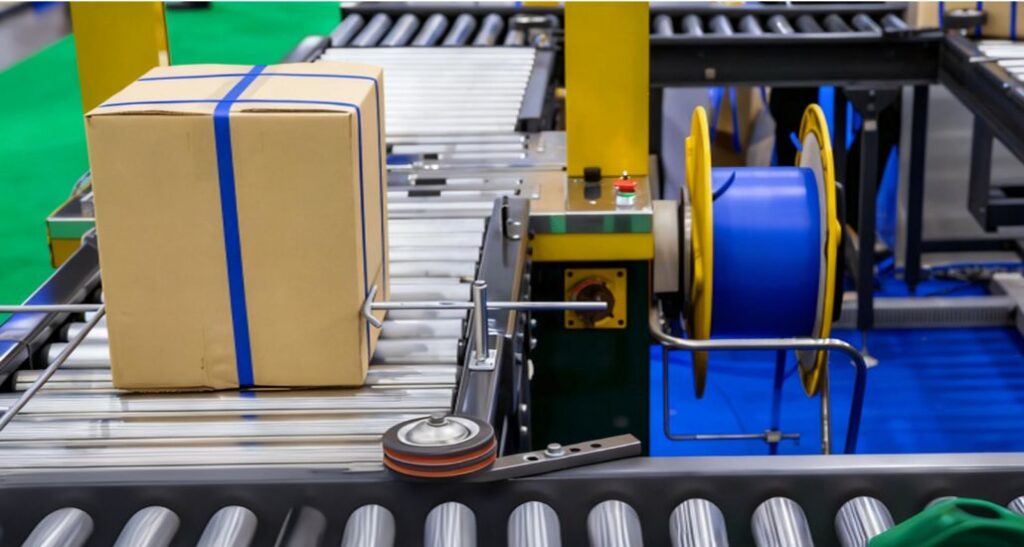

Commonly used in warehouses, e-commerce fulfillment centers, and manufacturing facilities, strapping machines are critical for securing packages like cardboard boxes, pallets, or bundled materials (e.g., metal rods, paper rolls).

How Strapping Machines Work?

The operation of a strapping machine follows a sequential, precision-driven workflow to deliver a tight, reliable bind:

1. Strap Feeding: The machine dispenses strap material from a coil or dedicated dispenser. It guides the strap around the package via a built-in arch or frame (customized to fit different load sizes).

2. Tensioning: Once the strap fully encircles the load, the machine applies controlled tension to pull the strap tight. This tension conforms to the item’s shape while avoiding tears, dents, or other damage to the packaged goods.

3. Sealing & Cutting: After achieving the correct tension, the machine seals the overlapping strap ends (via heat, friction, or mechanical fasteners, depending on the strap material). Excess strap is then cut off, and the secured package is released for further processing (e.g., moving to a shipping pallet via conveyor systems then palletizing the box by robot)