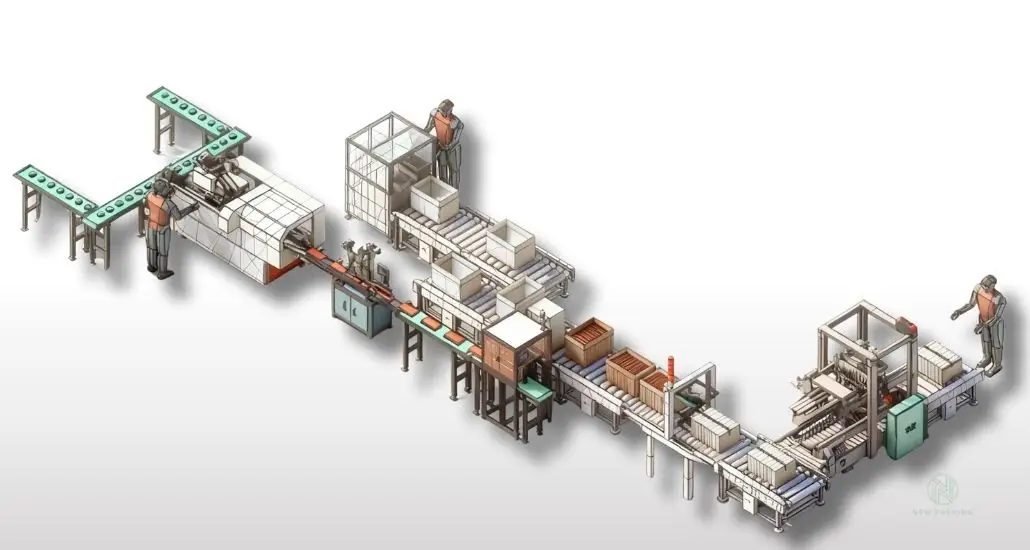

An automated carton packaging line is a semi-automated end-of-line system designed to streamline product packaging, assembly, and pre-shipment preparation. It integrates a sequence of specialized machines (arranged left-to-right in typical setups) to handle small goods (e.g., bottled items, packaged products) from individual carton loading to sealed shipping case collection.

This system combines machinery with human supervision (for oversight and maintenance), balancing automation efficiency with flexible control. It’s widely used in food, pharmaceutical, and consumer goods industries to optimize speed, packaging consistency, and labor costs.

Core Equipment in the Automated Carton Packaging Line

- Cartoning Machine: Loads individual products into empty cartons automatically, aligning items for secure enclosure.

- Case Erector Machine: Transforms flat corrugated blanks into ready-to-pack shipping cases

- Automatic Case Packer: Loads filled individual cartons into pre-erected shipping cases in a structured, space-efficient layout.

- Carton Sealer: Seals the flaps of both individual cartons and shipping cases

- Labeling and Transfer to Packing Station:: After cartoning, the sealed cartons pass through a labeling machine where a closure/seal label is applied. The labeled cartons are then conveyed to the automatic case packing station.

- Finished Goods Handling: After sealing is complete, the finished, sealed cases are conveyed to a collection point where an operator manually retrieves them.