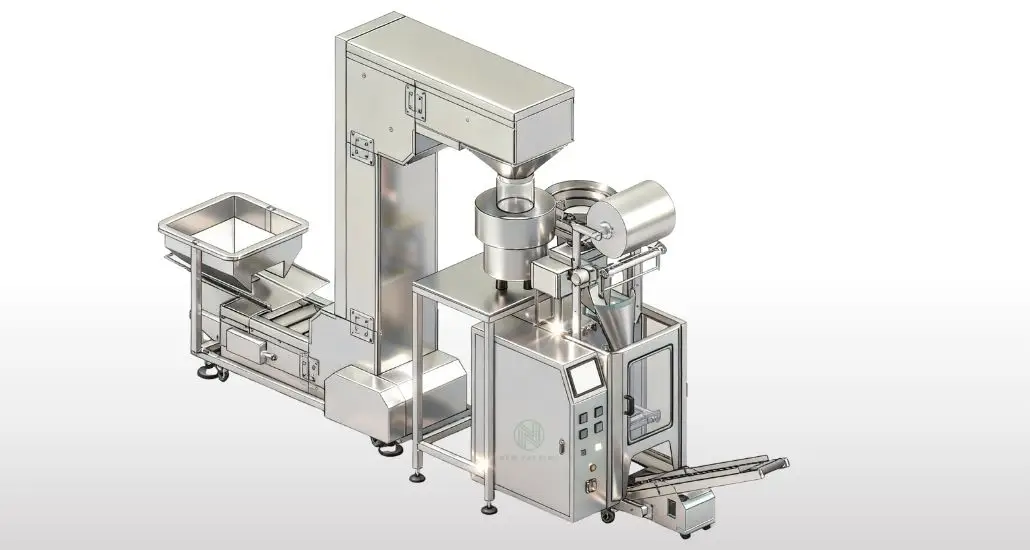

Overview of Our Dual-Precision Weighing & Packaging Machine

As a specialized packaging machine manufacturer, our Fully Automatic Weighing and Packaging Machine combines quantity counting and weight verification—solving the pain point of “inconsistent part quantities/weights” for small parts (hardware, electronic components, etc.).

Built with dual vibratory bowls (Main Tray + Sub Tray) and stainless-steel construction, this machine integrates feeding, counting, weighing, bagging, and sealing into one seamless workflow—ideal for medium-volume production lines (pair with our multihead weigher machine for high-volume needs).

Core Equipment Concept

The machine’s precision relies on a 2-tray vibratory bowl design, tailored for dual quantity/weight control:

- Main Tray: Bulk auto-feeding of small parts (e.g., screws, nuts) – stops feeding once the preset quantity/weight threshold is nearly met (avoids overfilling).

- Sub Tray: Individual “topping” feed – delivers 1–2 parts at a time to fine-tune quantity/weight to pixel-perfect precision (e.g., adjusting from 98 screws to 100, or 49.8g to 50g).

Packing Process: Step-by-Step

The stainless-steel machine (shown in the image) operates in 7 automated steps to ensure dual quantity/weight accuracy:

Step 1: Raw Material Loading: Small parts (hardware screws, electronic components) are loaded into the dual vibratory bowls (Main + Sub Tray) – the machine’s hopper sensors detect low stock and trigger alerts.

Step 2: Bulk Feeding (Main Bowl): The Main Tray’s vibratory system feeds parts in bulk to the weighing chamber. Built-in counters/load cells track quantity and weight in real time, pausing when 95% of the preset target (e.g., 95 screws / 48g) is reached.

Step 3: Precision Topping (Sub Bowl): The Sub Tray activates to feed 1–2 parts at a time, fine-tuning the batch to match the exact preset quantity and weight (e.g., topping up to 100 screws / 50g). This eliminates “under-pack” or “over-pack” errors.

Step 4: Bag Forming (Integrated VFFS Module): A built-in vertical form-fill-seal (VFFS) unit forms bags from a film roll (PE/PP laminates/Paper) – customizable widths fit small hardware pouches or electronic component kits.

Step 5: Filling & Sealing: The verified batch drops into the formed bag. The machine uses pneumatic back-seal straight-line sealing (recommended for smooth discharge) to create secure, neat seams – optional tear notches are added for end-user convenience.

Application Scope

This machine excels in packaging non-interlocking granular/small parts:

- Small Hardware: Screws, nails, nuts, washers, rivets

- Electronic Components: Buttons, fasteners, circuit board parts.

- Other Small Parts: Metal accessories, granular food ingredients, pharmaceutical tablets.

Contact our team for demos, quotes, or technical datasheets.